基本情報

出展製品・サービス

調和工業の製品案内

Product Guide of CHOWA KOGYO

主力商品はバイブロハンマ(振動杭打抜機)です。

国内製造シェアNo.1を誇り、油圧式、電動式、油圧ショベル装着型の品揃えがあります。まず、油圧式バイブロハンマですが、SRシリーズ、HVシリーズとあり、主力商品となっているのがSRシリーズです。小型・軽量・大起振力を誇り、シリーズ累計出荷400台を超え、杭打ち施工には欠かせない存在となっています。今回はSRシリーズの杭打ち能力を超える新モデル「ZV-35H」を展示会でお披露目いたします。

続いて電動式バイブロハンマのご紹介です。バイブロハンマのパイオニア的存在のCVシリーズから始まり、ZERO-VR/MRの品揃えがあります。この杭打機の良さは構造がシンプルで耐久性があるところです。デビュー当時から一定の人気があり、販売台数も年々伸ばしています。このシリーズの中にはΦ2300mmの鋼管杭に対応できる機種もあり、大規模施工工事で広く活躍しています。

最後に油圧ショベル装着型のご紹介です。LHVシリーズ、SR-04Pと CHVシリーズのタイプがあります。油圧ショベル装着型の為、自走が可能でコンパクトさゆえに都市型施工や狭あい地施工、桁下施工(CHVのみ)に適しています。

その他にも特殊工法に合わせたオーガー併用型や根入れ式鋼板セル工法用の連動式バイブロなど、様々な工法にも適応できる杭打抜機を製造しています。

また、硬質地盤への打込みには「ジェット併用バイブロハンマ工法」が最適でウォーター・ジェット・カッターがあります。こちらも充実した品揃えがあり主力商品の一つです。

Our main product is Vibro-hammers (vibratory pile driving machine).

The company boasts the largest share of the domestic manufacturing market and offers a full lineup of hydraulic, electric, and excavator-mounted models. First, the SR and HV series of hydraulic Vibro-hammers are available, with the SR series being the mainstay product. The SR series is our flagship product, boasting compact size, light weight, and large vibratory force, and has become an indispensable part of pile-driving construction, with cumulative shipments exceeding 400 units in the series. The new model ZV-35H, which surpasses the SR series, will be unveiled at this exhibition.

Next, we introduce electric Vibro-hammers. Starting with the pioneering CV series of vibro-hammers, we have the ZERO-VR/MR lineup. The beauty of this pile driver is its simple structure and durability. They have enjoyed a certain level of popularity since their debut, and their sales volume has been increasing year by year. Some models in this series can handle steel pipe piles with a diameter of 2300 mm, and are widely used in large-scale construction projects.

Finally, we introduce the excavator-mounted type, which is available in the LHV and CHV series and the SR-04P type. The compactness of this excavator-mounted type allows it to be self-propelled, making it suitable for urban construction and construction in narrow areas (CHV only).

We also manufacture other types of pile-driving machines that can be used for various construction methods, such as auger combination types for special construction methods and interlocking vibrators for the Embedded Steel Plate Cellular Method.

In addition, the “Vibro-hammer with Water Jet Cutter” method is best suited for driving into hard ground, and Water Jet Cutters are available. This is also one of our main products with a full lineup.

バイブロハンマ工法

Vibro-hammer Method

バイブロハンマを使った特殊工法をご紹介いたします。

まずは、ウォータージェット併用バイブロハンマ工法です。これは、バイブロハンマと高圧水を噴射するウォーター・ジェット・カッターを組み合わせ、硬質地盤に既成杭を打込む工法です。他の工法では施工が困難な場合や、長時間施工を要する岩盤層や玉石混じり礫層であっても、迅速かつ確実な施工を行うことができます。

次に、RSプラス®工法です。その特徴は、セメントミルクで杭先端に拡大根固め部を構成させることにより、杭単体より高い支持力が発揮できるというものです。施工手順は、まずウォータージェット併用バイブロハンマ工法により杭を打設した後、ジェット水噴射をセメントミルク噴射に切替え、杭先端に拡大根固め部を構成し、必要に応じて杭周面にもセメントミルクを充填させ完成します。この工法は、港湾空港技術研究所、日本製鉄、調和工業の3社の共同研究成果に基づき開発された工法で、低騒音・低振動での施工を実現し、高い支持力を発揮する、いま注目の施工方法です。

最後に、根入れ式鋼板セル工法です。これは、あらかじめ一体化されたセルを海底の地盤中に直接打ち込んでいく工法です。数台のバイブロハンマを同調運転させ、強力な振動エネルギーを均等にセルに伝える連動システムの開発により、困難だとされていた一体セルの打込を可能にしました。従来の鋼板セル工法が抱えていた数々の問題点を一挙に解決した工法です。

調和工業は、バイブロハンマの技術を進化させるとともに、日々新しい杭打抜工法の開発を積極的に推進しています。

We would like to introduce a special construction method using a Vibro-hammer.

First is the Vibro-hammer with Water Jet Cutter method. This method combines a Vibro-hammer and a Water Jet Cutter that injects high-pressure water to drive a pre-existing pile into hard ground. This method enables quick and reliable installation even in rock layers or gravel layers mixed with cobble stones, which are difficult to install with other methods or require a long installation time.

Next is the RS Plus® method. The RS-Plus® method is characterized by the use of cement milk to form an enlarged rooting zone at the pile tip, which provides higher bearing capacity than that of the pile alone. The construction procedure is as follows: first, the pile is driven using the Vibro-hammer method with Water Jet Cutter, then the Water Jet is switched to the cement milk Jet to form an enlarged rooting zone at the pile tip, and if necessary, the pile circumference is also filled with cement milk to complete the process. This method was developed based on the results of joint research by the Port and Airport Research Institute, Nippon Steel Corporation, and Chowa Kogyo, and is now attracting attention as a construction method that achieves low-noise, low-vibration construction and high bearing capacity.

Finally, there is the Embedded Steel Plate Cellular Method. In this method, pre-assembled cells are driven directly into the seabed. The development of an interlocking system that synchronizes the operation of several Vibro-hammers and evenly transmits powerful vibrational energy to the cells has made possible the casting of integrated cells, which had been considered difficult. This method solves all the problems of the conventional steel plate cell method.

Chowa Kogyo is actively promoting the development of new pile driving methods on a daily basis as well as advancing its Vibro-hammer technology.

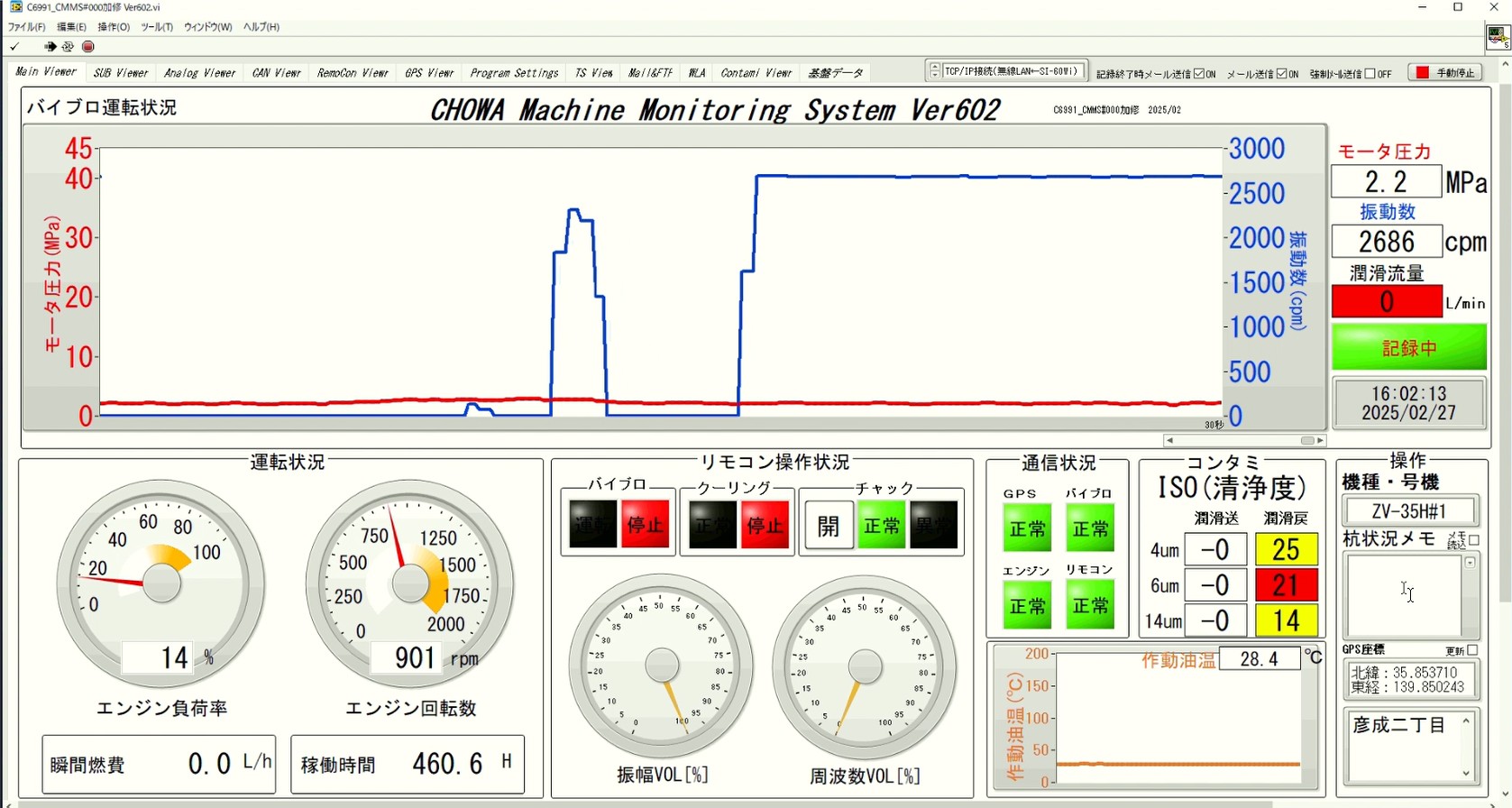

CMMS:調和機械モニタリングシステム

CHOWA MACHINE MONITERING SYSTEM

調和機械モニタリングシステムとは、機械(当社製品:バイブロハンマ)の稼働状況や状態をリアルタイムに把握し、異常を検知してアラートを発信するシステムです。このシステムの導入で機械の稼働率が把握でき、生産性の向上、また設備の突発事故の防止などに役立ちます。具体的には、以下3つの項目について監視しています。

(1)ユニット情報(エンジン稼働情報、作動油情報)

(2)リモコン操作情報(運転、停止、周波数Vol、振動Vol、チャック開中閉)

(3)打設情報(モータ圧力、振動数、メモなど)

(1)~(3)の監視を行うことで得られるメリットは、次の通りです

・ 稼働時間の把握や現場環境による機材の消耗具合の監視により、ベストなタイミングで部品交換時期の提案が可能になります。

・ 油圧機械システムの故障原因の80%と言われる作動油のコンタミ量(汚染度)の把握、そしてその温度変化を監視することで、突然の故障を未然に防ぐ事が可能になります。

・ バイブロハンマの挙動等を事前に確認できることにより、メンテナンスサービスの必要性のご提案が可能になります。

このシステムは、ユーザーの皆様により快適に、より長くバイブロハンマを愛用していただくために考案したシステムです。

The CHOWA Machine Monitoring System is a system that monitors the operating status and condition of a machine (our product: Vibro-hammer) in real time, detects any abnormalities, and sends out alerts. This system enables us to monitor the operating rate of the machine, which is useful for improving productivity and preventing sudden accidents of the equipment. Specifically, the system monitors the following three items;

(1) Unit data (engine operating data, hydraulic oil information)

(2) Remote control operation system (operation, stop, frequency Vol, vibration Vol, chuck open/close)

(3) Driving information (motor pressure, vibration frequency, notes, etc.)

The advantages of monitoring (1) to (3) are as follows;

a) Monitoring of operating hours and wear and tear of equipment due to the site environment will enable proposals on the best timing for parts replacement.

b) Prevent sudden breakdowns by monitoring the amount of hydraulic oil contamination, which is said to be 80% of the causes of hydraulic system problems, and by monitoring changes in the temperature of the oil.

c) being able to check the performance of the Vibro-hammer in advance, it is possible to suggest the need for maintenance service.

This system is designed to make users more comfortable and prolong their use of Vibro-hammers.