基本情報

出展製品・サービス

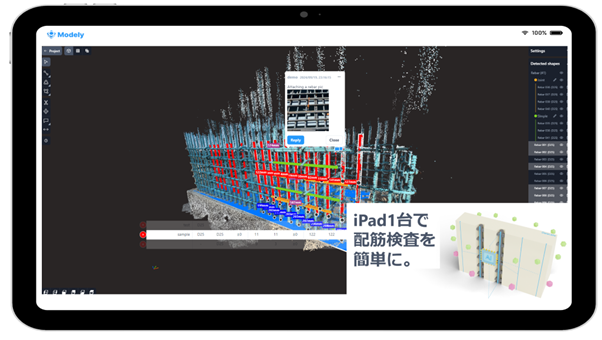

iPad1台で配筋検査を簡単に3D配筋検査システムModely

Modely Revolutionize rebar inspection - just an iPad does it all!

NETIS活用促進技術に選定!導入社数200社を突破!配筋検査の課題を解決します!

Modelyは、iPad等で配筋の点群データを取得し、3次元モデルに変換することで配筋検査項目を自動で帳票化できるサービスです。

【PR】

Modelyは2023年4月にリリースされてからわずか2年弱で、配筋検査システムで唯一NETIS活用促進技術に認定され、NETIS-VEへ昇格しました。 導入社数は200社を超え、国交省直轄工事や都道府県発注工事、民間発注者の工事においても利用実績があります。

以下のような理由で選ばれています:

・写真を活用するシステムでは難しい広い範囲を一度に計測できる

・点群を活用することで計測の安定性が向上

・専用デバイスではなくiPadで利用できる

・ダブル配筋等の計測の安定性

・頻繁なアップデートによる機能向上

【特徴】

・点群や作成したモデルは発注者に共有可能で、コメントによる確認会話も可能

・3次元データをベースとしているため、「デジタルデータを活用した鉄筋出来形計測の試行要領(案)」に規定されている「鉄筋本数、鉄筋径、配筋間隔、鉄筋かぶり」だけでなく、ダブル配筋・環状型フープ筋・円周上に並ぶ鉄筋(フーチング等)についてもモデル化・計測が可能

・生成した3次元モデルのエクスポートが可能であり、他の3次元データと合わせて活用することで、BIM/CIM適用を推進 ・継ぎ手長についても計測が可能

・PDFデータや画像データのアップロードが可能

・EX-TREND武蔵との連携により、設計値と実測値の入力がシームレスに可能

Recognized as a Promoted Technology under NETIS! Adopted by over 200 companies, Modely solves on-site rebar inspection challenges.

Modely is a service that captures point cloud data of rebar using an iPad and converts it into 3D models, allowing for the automatic generation of inspection reports.

[PR]

Since its release in April 2023, Modely has been the only rebar inspection system recognized as a Promoted Technology under NETIS, achieving an upgrade to Verified Technology (VE) status in less than two years. It is now used in government-led projects by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT), as well as in prefectural and private sector construction.

Why it’s chosen:

Wide-area measurement, which is difficult with photo-based systems

Improved measurement stability using point cloud data

iPad-based, with no dedicated device required

Stable detection even for double reinforcement

Frequent updates with continuous feature improvements

Features:

Share point cloud data and generated 3D models with project owners, with comment-based communication also available

Based on 3D data, enabling measurement of rebar count, diameter, spacing, and cover thickness as specified in the draft Guidelines for Digital Rebar Measurement issued by MLIT. Also supports modeling and measurement of double reinforcement, hoop reinforcement, and circumferentially arranged rebars such as footings

Exportable 3D models support BIM/CIM workflows

Capable of measuring splice lengths

Upload PDF and image data

Seamless input of design and actual values via EX-TREND Musashi integration

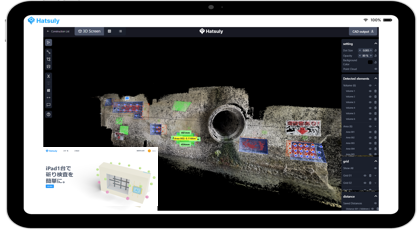

3Dインフラ補修システムHatsuly

3D infrastructure maintenance system Hatsuly

インフラ補修工事で省力化を実現!導入社数50社を突破したNETIS登録技術

「Hatsuly」は、橋梁補修工事における、調査や表面被覆工や剥落防止工の出来形検査、断面修復工における出来形検査など、インフラ補修における検測を効率化するシステムです。スマホやタブレットで取得した3次元データを利用して、クラックの延長、面積の算出、はつり深さ、体積等を自動算出し、帳票を作成できるアプリです。3次元データや帳票を発注者と共有することや、出力することも可能です。インフラ補修工事の調査や出来形管理において、大幅な省力化を実現することが出来ます。

【PR】

HatsulyはNETIS登録技術であり、株式会社IHIインフラ建設、株式会社新井組、入交建設株式会社を始めとして50社以上に導入いただいています。国交省、都道府県、市町村、民間発注者工事などでの導入実績があります。

以下のような理由で選ばれています:

・従来では多くの補修箇所の計測、写真管理を複数人で行っていた作業が、一人で写真管理を省略して実施できる

・補修箇所について、必要な数量の算出が出来る

・補修箇所について、3Dモデルでわかりやすい見た目で確認、説明が出来る

・専用デバイスではなくiPadで利用できる

・頻繁なアップデートによる機能向上

【特徴】

・断面修復工において大きな省力化を実現

・クラック注入工、剥落防止工等での出来形検査に必要な機能を実装

・将来的には損傷展開図(2DCAD図面)の自動作成機能などを実装予定

Achieve Labor Savings in Infrastructure Repair! Over 50 Companies Have Adopted This NETIS-Registered Technology

Hatsuly is a web system that streamlines inspection processes in infrastructure repair work, particularly in bridge repair projects. It enhances efficiency in tasks such as condition assessment and as-built inspection for surface coating and anti-spalling work. Using 3D data captured via smartphones or tablets, Hatsuly automatically calculates crack length, surface area, chipped depth and volume, and more. The system also generates exportable reports and enables easy data sharing with owners. It significantly reduces the workload for as-built inspections in infrastructure repair work.

[PR Section]

NETIS-registered and already in use by more than 50 contractors — including IHI Construction Service Co., Ltd., ARAIGUMI CO.,LTD., and IRIMAJIRI CONSTRUCTION CO., LTD. — Hatsuly has been deployed on infrastructure projects commissioned by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT), local governments, and private sector clients.

Why it’s chosen:

Tasks that once required multiple workers using photo-based measurement can now be handled by one person — without photo documentation

Accurately calculates quantities needed for repair work

Provides easy-to-understand 3D visual representations for reviewing and explaining repair areas

Works on standard iPads — no specialized equipment required

Regular updates continuously improve functionality

Strengths:

Significant labor savings in concrete surface repair work

Equipped with the necessary features to perform as-built inspections for crack injection and anti-spalling work

A future update will introduce automatic generation of 2D drawings showing damaged areas